The new Generation of Electrochemical Gas Sensors

The EC Sense solid polymer electrochemical technology represents a groundbreaking advancement in electrochemical detection. The liquid core was polymerized bringing a wide range of advantages and new possibilities to the world of electrochemical sensors. EC Sense’s three product lines – Gas Sensors, Gas Sensor Modules and Gas Sensor Devices – use this innovative Solid Polymer Electrochemical Technology to provide small, fast response and long lifetime solutions to our customers.

What is an Electrochemical Gas Sensor?

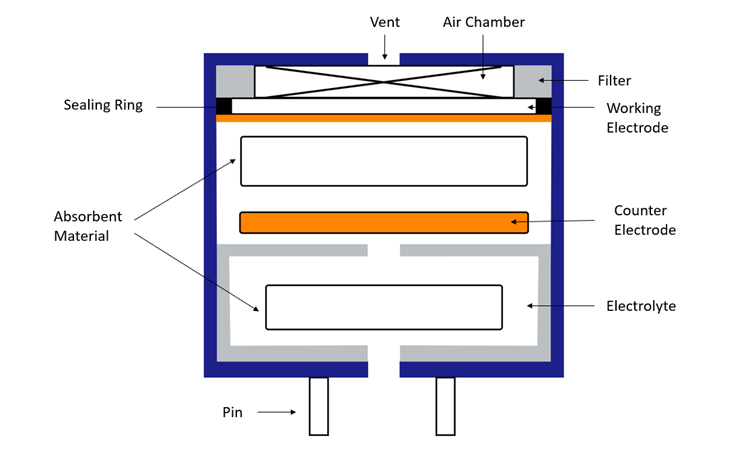

Electrochemical sensor technologies continue to be increasingly used for many different analytical gas detection applications, such as personal monitoring. A low-cost sensor with a simple user interface, small size, and minimal power consumption is in high demand. The majority of these sensors are amperometric sensors that have measuring and counter-reference electrodes and liquid electrolytes.

An electrochemical gas sensor works in a similar way to a fuel cell. For instance, the fuel cell converts hydrogen into water. This generates a large energy output and currents in the ampere range. In the amperometric gas sensor, the target gas diffuses to a measuring electrode where it is oxidized or reduced. However, the output signal is very small in the nA or µA range, but measurable, due to the low concentration of ppm or ppb and due to a diffusion limitation of the sensor.

Modern fuel cells no longer work with liquid electrolytes, but now contain so-called SPE- (Solid Polymer Electrolyte) membranes, which have ionic conductivity to transport the current within the fuel cell.

For more than 40 years, most commercially available electrochemical gas sensors still contain liquid electrolytes such as H2SO4, H3PO4 or salt solutions. Our goal and dream was to apply the polymer electrolyte technology to electrochemical sensors. Here, we highlight the advantages that were achieved with EC Sense’s polymer electrolyte sensors.

Why Electrochemical Gas Sensors?

Electrochemical sensors are sensitive to various gas molecules such as CO, NH3, SO2, NO, NO2, O2, HCN, O3, PH3, SiH4, HF and H2. They offer one of the most energy-efficient approaches combined with analytical performance that includes sensitivity and selectivity at relatively low cost.

The industrial standard – Liquid Electrochemical Gas Sensors

Traditional “old style” Liquid Electrochemical Gas Sensors are larger in size since they must contain a liquid reservoir and expansion tank to compensate for moisture absorption by the hygroscopic electrolyte or to serve as a water source in the event of a dry environment. Basically, there is always a risk of leakage or drying out, depending on the environmental conditions.

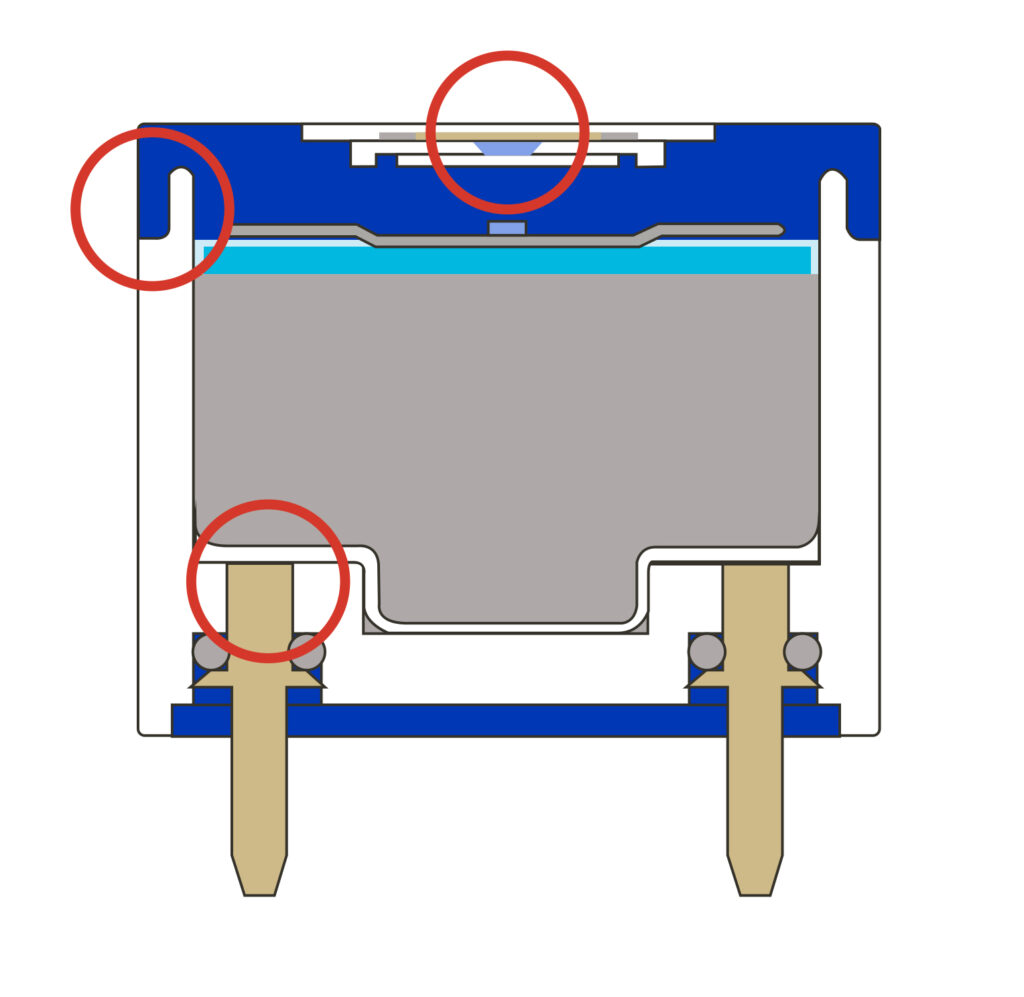

The three circles show the weak points of a liquid electrolyte-based sensor: The contact seals, the gas diffusion membrane and the sealing of the membrane.

Challenging the standards – The innovative Solid Polymer Sensor Design

The basic structure of our polymer electrolyte sensor consists of a ceramic wafer containing holes next to a measuring electrode and next to the counter electrode. On the contact side, a measuring -, a reference – and a counter electrode are printed on the ceramic wafer in a specific design. Depending on the application, we can design the structure in different variants.

First the electrodes with a novel metal-containing slurry are printed onto the ceramic using an automatic screen-printing process. Then a polymer electrolyte layer and finally a water-retaining layer, which stabilizes the internal water balance of the sensor, acts as a proton transport material and also functions as an ion-conducting layer. A final layer of silicone rubber seals the sensor from the environment.

The automated printing processes enables the simultaneous production of a large number of sensors, which means that the sensors can be produced at consistently high quality and low cost. This allows the sensors to be used in applications that were previously impossible for economic reasons.

Our variety of electrochemical sensors are now used in high volumes in both stationary and portable applications. Polymer electrolytes in combination with ionic liquid polymer electrolytes are typically used for operation at low temperatures and in humid or dry conditions.

Gas sensors using polymer electrolytes are not yet as thermally robust as the devices that can be made using solid-state materials such as semiconductor sensors or high-temperature zirconia electrolyte sensors. However, amperometric and potentiometric devices typically provide higher selectivity than semiconductor sensors and do not consume electricity.

What are the Advantages of a Solid Core?

Solid polymer electrochemical sensors are cost-effective for large-scale production and ensure consistent quality through automation. Their compact size, low power consumption and broad temperature range allow for a seamless integration into a wide range of applications. The sensors can perform measurements in the ppb range as they are noise-free and have low drift. The solid core eliminates the risk of leakage or drying out and ensures consistent measurements with high accuracy even in high humidity environments, contributing to their long lifespan.

Solid Polymer Electrochemical Technology offers flexibility in design and size since the core is dry and contains no liquid electrolytes. Traditionally, electrochemical sensors are used to detect toxic gases in industrial settings. The concept of a dry electrochemical cell based on a solid polymer electrolyte challenges not only the design restrictions of the gas sensor, but also the traditional applications for electrochemical cells. This revolutionary technology enables new and innovative mechanical designs for the finished cell.

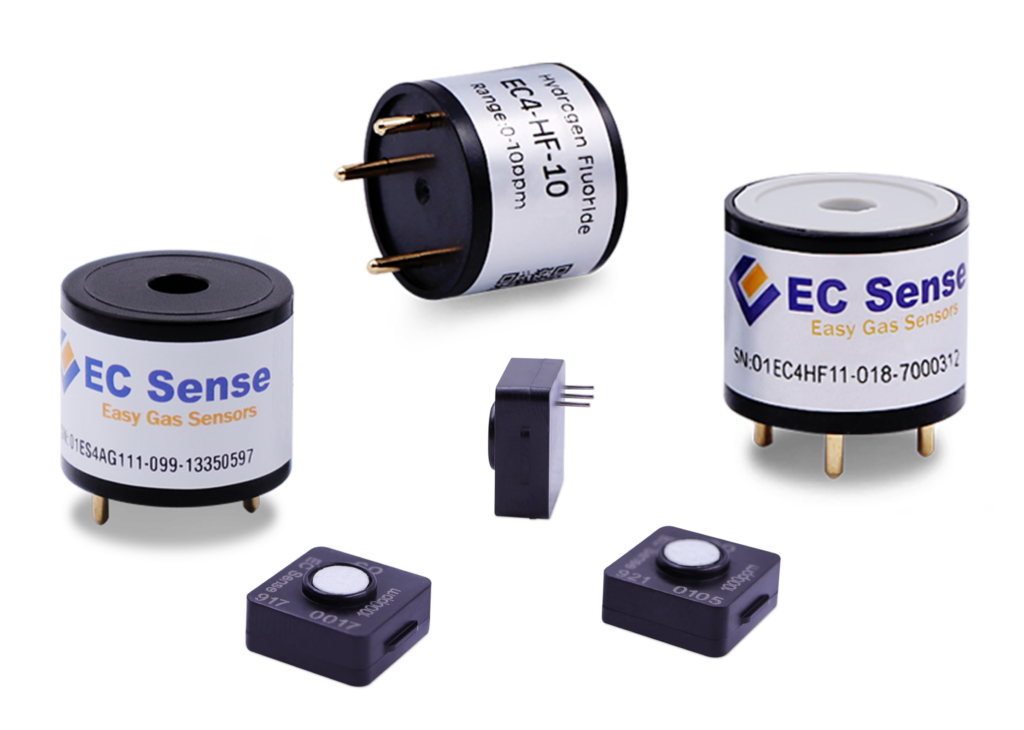

The sensor technology is utilized in EC Sense’s ES1 & ES4 product lines.

Additionally, the size of the ES1 cell has been reduced in all dimensions allowing the construction of smaller and more compact gas analyzers. EC Sense still offers the industrial standard ES4 size, but with the innovative solid polymer electrochemical technology at the core.

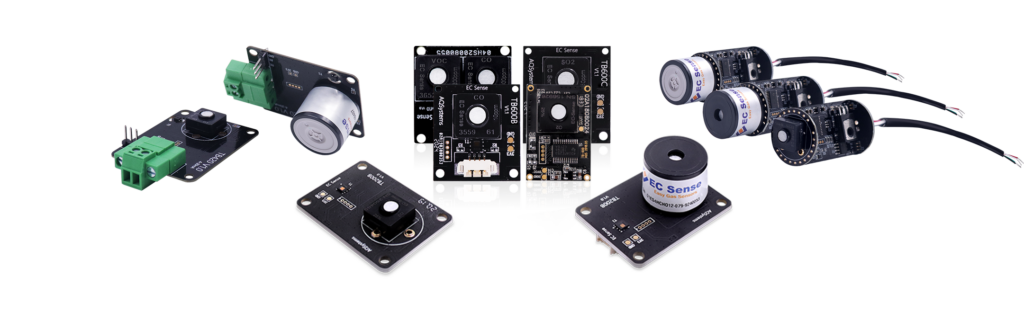

EC Sense’s Gas Sensor Module product line combines the state-of-the-art Solid Polymer Electrochemical Gas Sensor with a sophisticated circuit board to create an easy-to-use gas detection solution.

Various application solutions are also covered by EC Sense’s Gas Sensor Devices: ECtox, ECnose, ECgaspoint, Stox, StoxPro, which also use the innovative Solid Polymer Technology.