- Carbon Monoxide

- Formaldehyde

- Microbial Contaminants (Mold, Dust Mites, etc.)

- Second-Hand Tobacco Smoke

- Volatile Organic Compounds (VOC)

The meat consumption has risen steadily in recent years. There is already a large industry that breeds such “meat” at top speed.

A chicken’s life is only 8 weeks long. A pig’s life on a small farm is about a year long; in an industrial farm it is only 120 days. In order to maximize profit, the population in an industrial animal breeding facility is constantly raised. This increases the risk that this population will be affected by diseases.

The pollution is caused by the respiration of the animals and by the digestion of the food. Humidity increases due to the high population and because the waste remains in place for a while. Many methane gases are produced during digestion of green fodder. NH3 and H2S are toxic gases and harm animals in higher concentrations.

To optimize cultivation and make the shelf life of our future food acceptable, the following air quality basics should be observed:

1. Temperature and Humidity: Humidities above 70% r.H. and temperatures below 10°C or above 30°C stress our future food.

2. Odors generated by the waste of the animals: Same as us humans, animals produce CO2. However, the animal waste falls to the ground and produces CO2 in the air. Due to a high animal density, the concentration inside a barn is higher than outside. High CO2 levels make the animals tired and weak, sometimes even aggressive. Farmers have to add drugs to the diet to control the situation.

Good air quality would reduce these problems to a minimum.

Typically, the concentration in a piggery should be below 10ppm. At this level, the pigs remain healthy.

At concentrations above 20ppm NH3, the pigs’ health becomes unstable. The following health risks may occur:

a. Lung infection

b. Heart and cardiac system problems

c. Aggressive behavior, tails and ears are bitten off.

The animals’ health degrades faster, infecting others and not growing as quickly and successfully.

To counteract these problems, the following activities have to happen:

a. Animal wastes are mainly NH3 ammonia, sulfide, amines. Keep this level at least below 15ppm.

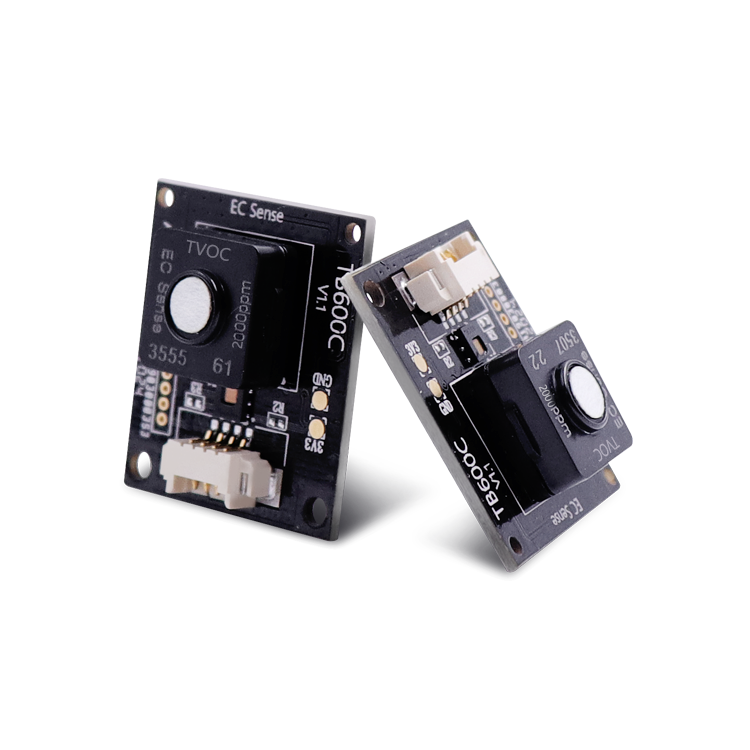

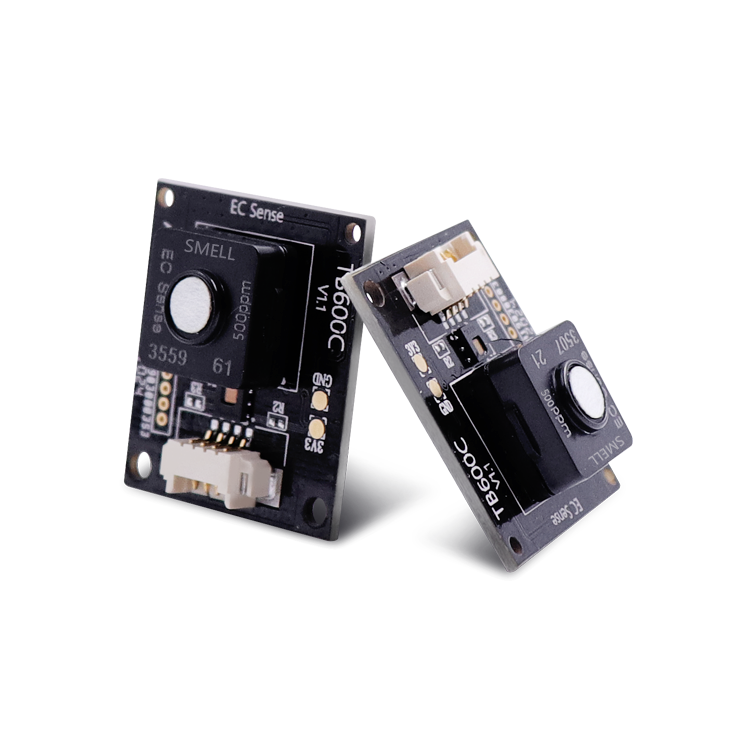

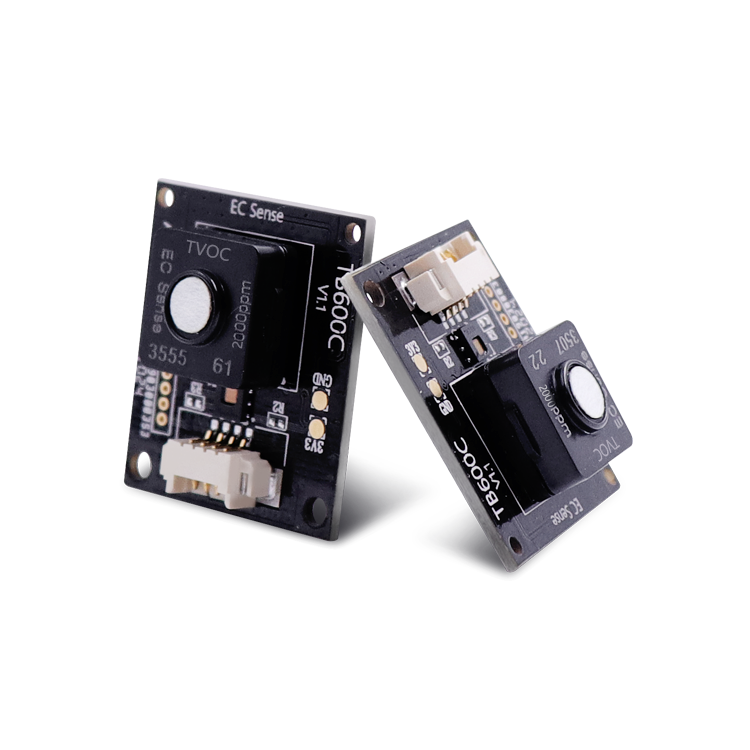

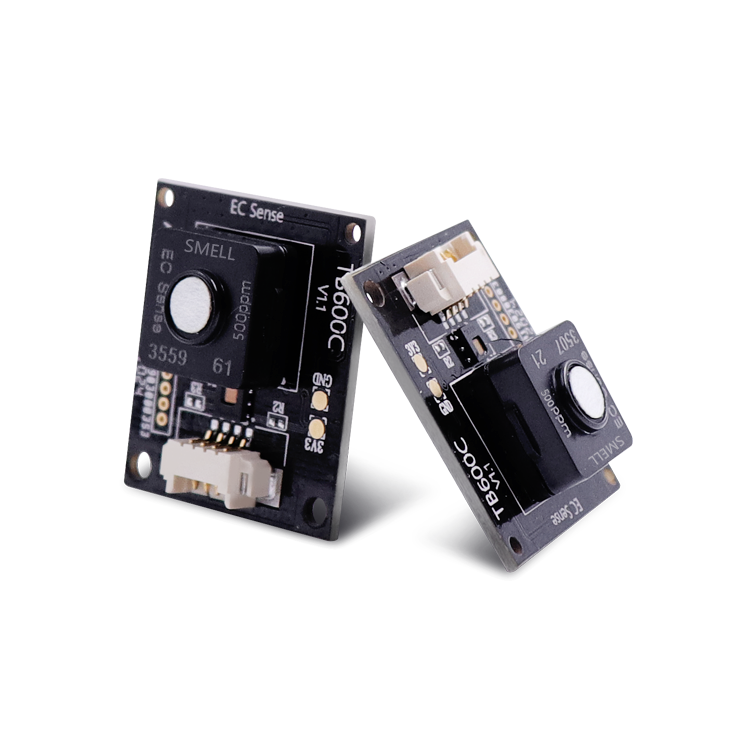

b. Measure the NH3 concentration with the ECtox, the only long-life Gas Sensor available at the moment.

c. In case the values are too high air exchange is required.

High NH3 concentrations leaving the piggery will also enter the neighborhood. The gas should be cleaned up before it leaves the stall area. Ozone would be a good cleaning agent for this application.

However, the concentration level which affects the animals is in different ranges. As chickens are smaller, they are also affected by smaller ammonia concentrations. The controlled level should be around 5ppm. Only at this level the growth runs at full speed and less medicine is needed to stabilize the animals’ health.

Our NH3 Gas Sensor, like any other Gas Sensor on the market, also has problems with continuous background concentrations, whose lifetime quickly deteriorates due to the continuously high ammonia concentrations in the environment. The reason for this is a drift of the zero line over time.

Therefore, EC Sense created an instrument to counteract this common problem in animal husbandry gas sensing.

The ECtox has a free zero line. The technology to detect NH3 is called coulometry. This type of detection does not require calibration because the NH3 is analysed each time it is detected.

Advantages of the ECtox: